Understanding the Latest Trends in Fabrication and Welding

Introduction to Modern Fabrication and Welding

The fabrication and welding industry is constantly evolving, driven by technological advancements and emerging trends. Understanding these trends is crucial for professionals who wish to remain competitive and efficient in their operations. This post explores some of the latest trends that are shaping the world of fabrication and welding today.

Automation and Robotics in Welding

One of the most significant trends in welding is the increasing use of automation and robotics. Automated welding systems are becoming more prevalent as they offer higher precision, consistency, and productivity. These systems are particularly beneficial for repetitive tasks, allowing human workers to focus on more complex projects.

Robotic welding also minimizes human error and reduces the risk of workplace injuries. As technology advances, we can expect even more sophisticated robotic systems that can handle a wider range of materials and welding techniques.

Benefits of Automation

- Increased efficiency and productivity

- Improved accuracy and precision

- Reduced labor costs

- Enhanced safety for workers

Advancements in Welding Materials

Another trend in the industry is the development of new welding materials and techniques. The push for lighter, stronger, and more durable materials is influencing how welding is performed. Innovations in alloys and composite materials are expanding the possibilities for fabricators and welders.

These advancements not only improve the quality of the welds but also enhance the overall performance of the fabricated structures. As material science continues to progress, we can expect further breakthroughs that will transform traditional welding practices.

Sustainability in Fabrication Practices

Sustainability is becoming a priority across industries, and fabrication is no exception. Companies are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes using sustainable materials, minimizing waste, and optimizing energy consumption during the production process.

Moreover, recycling and reusing materials have become more common in fabrication processes. By focusing on sustainability, businesses not only contribute to environmental conservation but also appeal to environmentally conscious consumers.

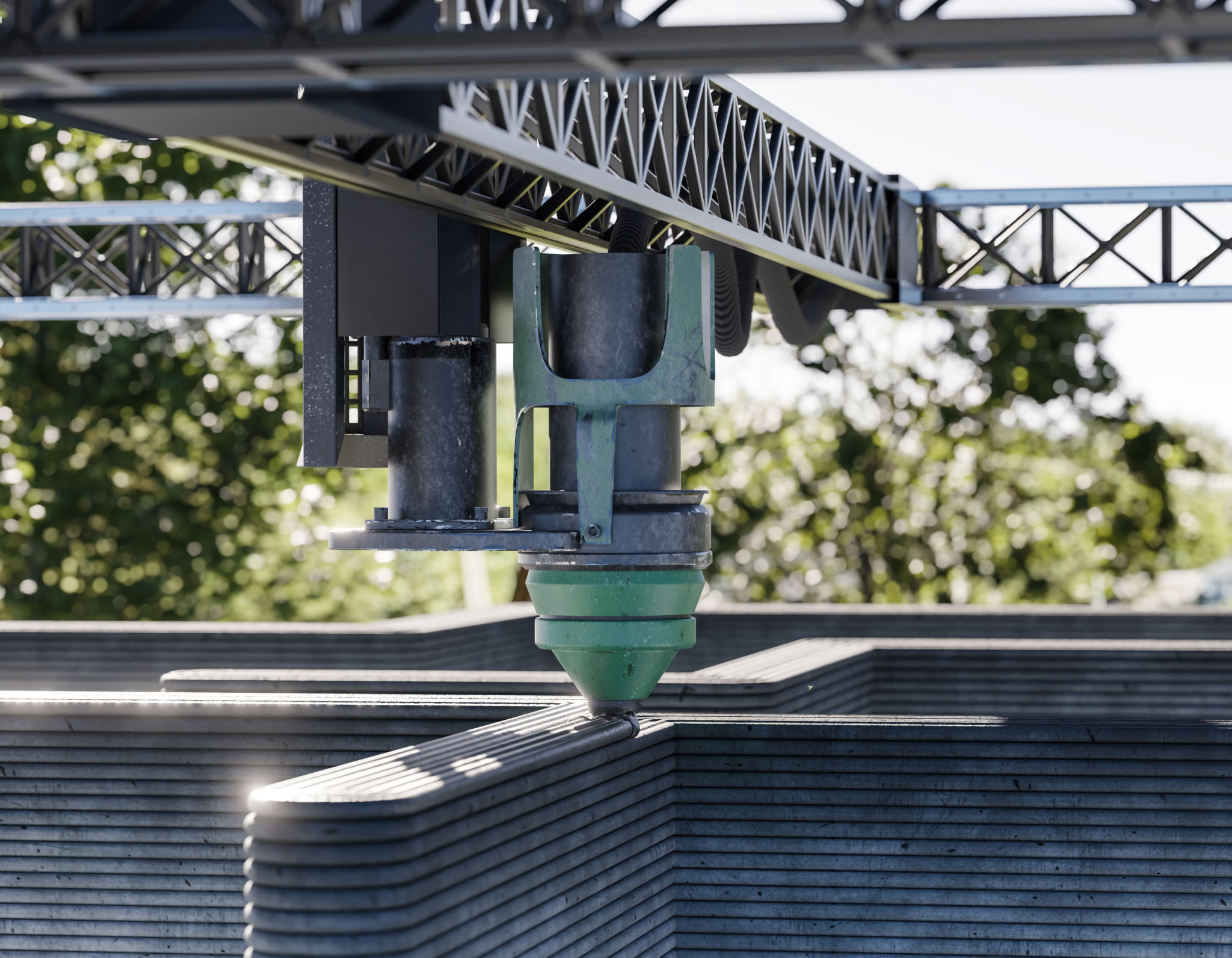

The Rise of Additive Manufacturing

Additive manufacturing, or 3D printing, is another trend that is gaining traction in the fabrication sector. It offers unparalleled flexibility and customization options, allowing for the creation of complex geometries that were previously impossible with traditional methods.

This technology is particularly beneficial for prototyping and small batch production, where time and cost efficiency are crucial. As 3D printing technology advances, it is expected to become an integral part of the fabrication landscape.

The Importance of Skill Development

With these technological advancements comes a growing need for skilled labor. Continuous education and training are essential for workers to keep up with new tools, techniques, and safety standards. Welding and fabrication professionals must adapt to new technologies and refine their skills to maintain their competitive edge.

Many companies invest in training programs to ensure their workforce is capable of handling the latest equipment and methodologies effectively. This investment in human capital not only boosts productivity but also fosters innovation within the organization.

Conclusion

The landscape of fabrication and welding is rapidly changing, driven by technological innovation and shifting industry priorities. By embracing these trends, businesses can enhance their operations, improve product quality, and remain competitive in a dynamic market. Staying informed about these changes is essential for anyone involved in this ever-evolving industry.