Understanding the Differences: Custom vs. Standard Fabrication

Introduction to Fabrication

Fabrication plays a crucial role in various industries, from construction to manufacturing. Understanding the differences between custom and standard fabrication can help businesses make informed decisions about their projects. Both approaches have their unique benefits and applications, but knowing which one suits your needs can be the key to success.

What is Standard Fabrication?

Standard fabrication involves the production of pre-designed and pre-manufactured items. These are typically produced in large quantities, allowing for consistency and cost-effectiveness. Industries often rely on standard fabrication for items that do not require specialized specifications or design modifications.

The advantages of standard fabrication include reduced costs, faster production times, and ease of replacement or repair. However, this approach may not be suitable for projects that require unique or complex designs.

Understanding Custom Fabrication

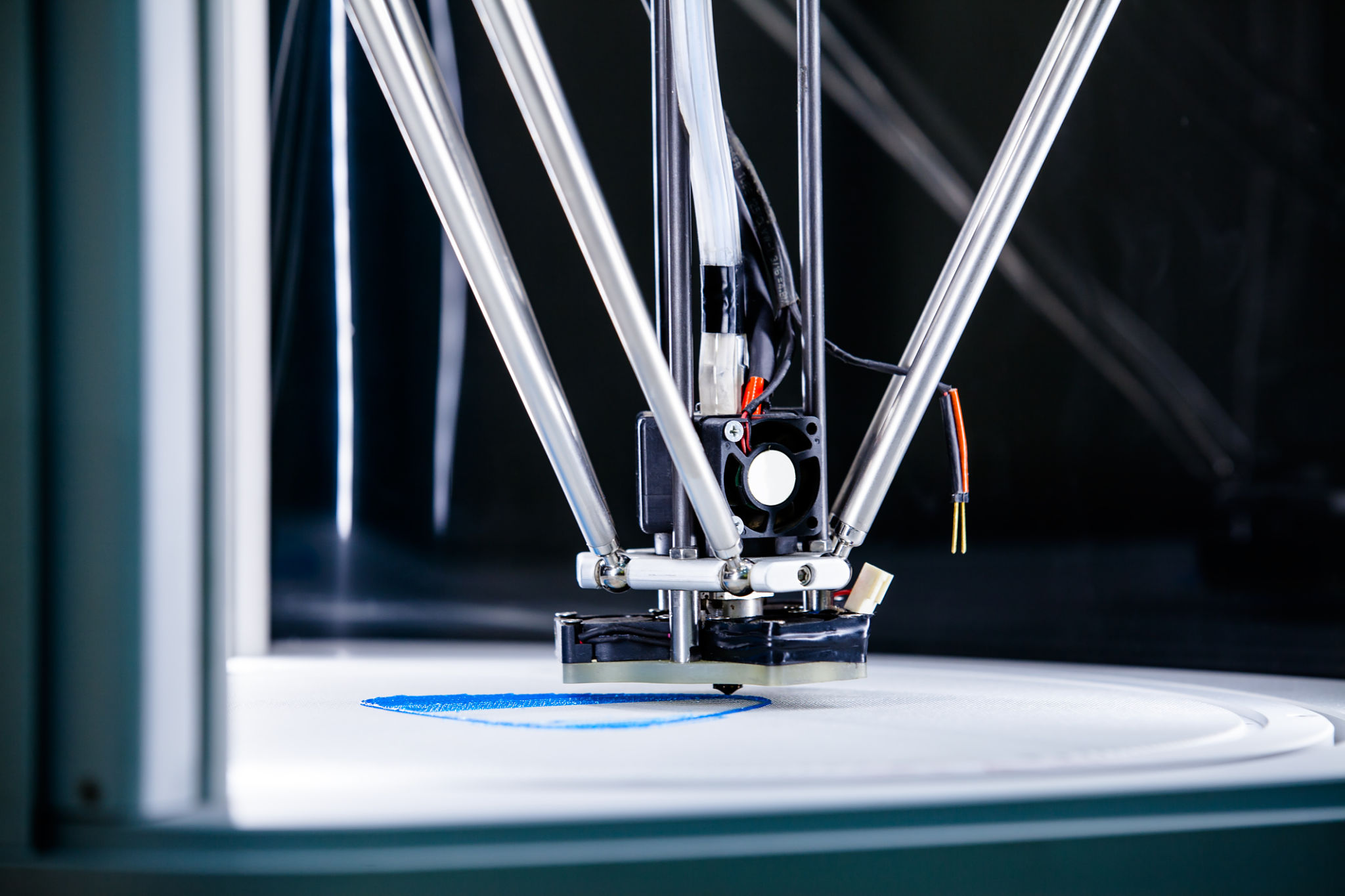

In contrast, custom fabrication is tailored to meet specific requirements and design preferences. This process allows for greater flexibility and creativity, as items are produced based on precise client specifications. Custom fabrication is ideal for projects where standard solutions fall short.

While custom fabrication may involve higher costs and longer production times, it offers unparalleled quality and uniqueness. This approach is particularly beneficial for industries where precision and customization are paramount.

Comparing Costs and Benefits

When choosing between custom and standard fabrication, it's essential to weigh the costs against the benefits. Standard fabrication is often more budget-friendly due to economies of scale, whereas custom fabrication requires a higher investment but delivers personalized results.

Consider the long-term implications of your choice. Custom fabrication might offer better durability and performance, potentially saving money on repairs and replacements in the future.

Applications in Various Industries

The application of custom versus standard fabrication varies widely across industries. In construction, standard components like beams and girders are often used for straightforward projects, while custom parts are necessary for complex architectural designs.

Similarly, in automotive manufacturing, standard parts are commonly used for mass-produced vehicles, whereas custom parts are crucial for high-performance or luxury models. Understanding these applications can guide businesses in selecting the right fabrication method.

Making the Right Choice

Ultimately, the decision between custom and standard fabrication should be based on the specific needs of your project. Consider factors such as budget, deadline, design requirements, and long-term performance when making your choice.

Collaborating with experienced fabricators who understand both methods can provide valuable insights and recommendations tailored to your project goals.

Conclusion

Both custom and standard fabrication offer distinct advantages and are suited for different scenarios. By understanding the differences and carefully evaluating your project's requirements, you can make an informed decision that aligns with your objectives and ensures success.