Exploring the Latest Trends in Fabrication Engineering in Victoria

Introduction to Fabrication Engineering Trends

Fabrication engineering is witnessing a renaissance in Victoria, driven by technological advancements and innovative methodologies. As industries strive for increased efficiency and sustainability, understanding the latest trends in this field becomes crucial. This post delves into the emerging trends shaping the future of fabrication engineering in Victoria, offering insights into the techniques and technologies propelling the industry forward.

Advanced Materials and Their Applications

The use of advanced materials is redefining fabrication engineering. Engineers are increasingly adopting materials like carbon fiber composites and smart alloys, which offer superior strength and flexibility. These materials are not only enhancing product performance but also contributing to sustainability by reducing waste and energy consumption during manufacturing processes.

Moreover, the integration of nanomaterials into fabrication processes is opening new avenues for innovation. These materials improve product durability and performance, paving the way for applications in various sectors, including automotive and aerospace industries.

Automation and Robotics

Automation is at the heart of modern fabrication engineering. The integration of robotics into fabrication processes has significantly improved precision and efficiency. Robots are now capable of performing complex tasks with minimal human intervention, reducing errors and increasing production speed.

In Victoria, the adoption of collaborative robots, or cobots, is gaining momentum. These robots work alongside humans, enhancing productivity while ensuring safety in the workplace. Their ability to adapt to various tasks makes them invaluable assets in the fabrication industry.

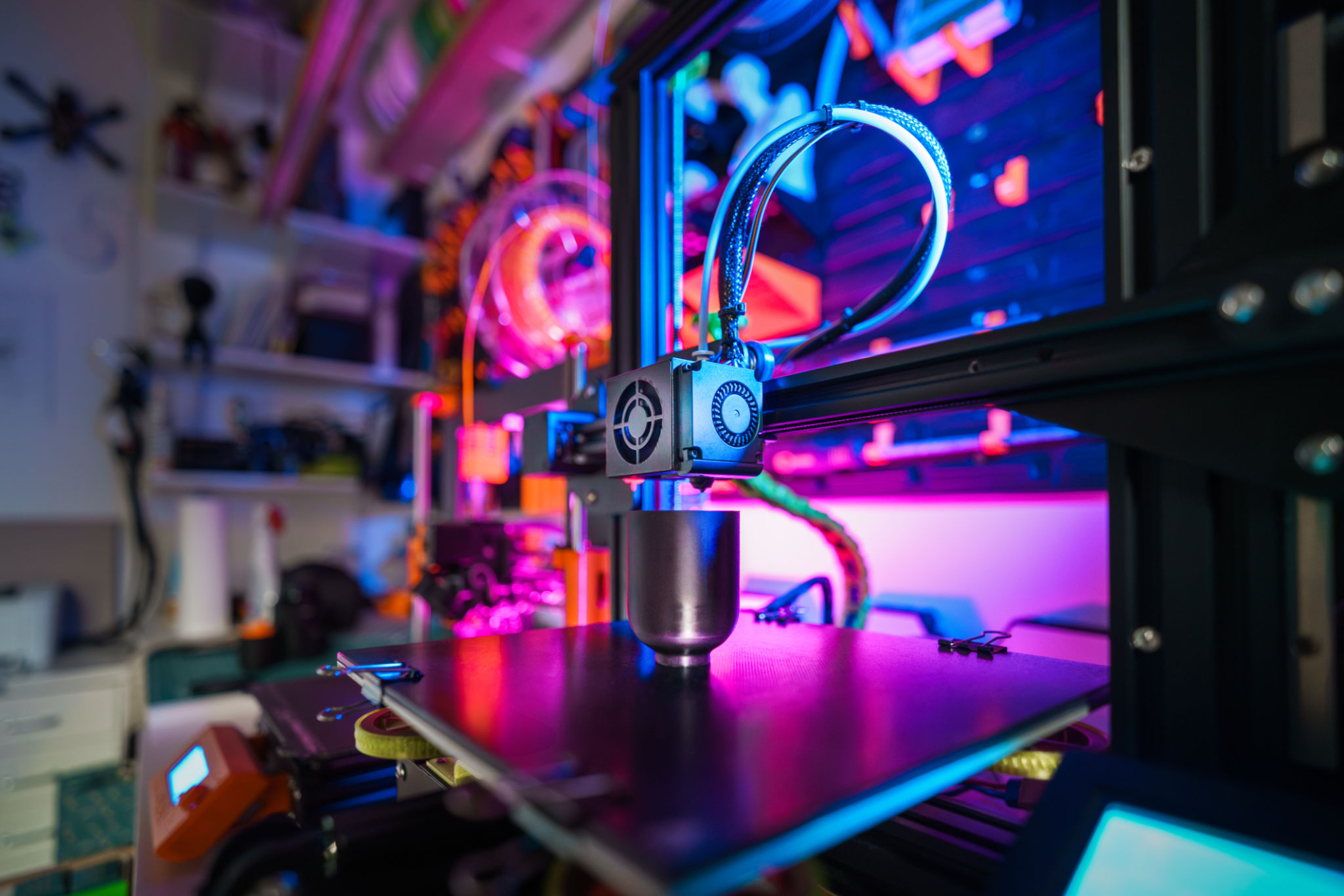

3D Printing Revolution

3D printing, or additive manufacturing, continues to revolutionize fabrication engineering. This technology allows for the creation of complex geometries that were previously impossible with traditional methods. In Victoria, companies are leveraging 3D printing to produce prototypes rapidly, reducing development time and costs.

The flexibility offered by 3D printing also enables customization in manufacturing, allowing businesses to cater to specific client needs efficiently. As materials and printing technologies advance, the applications of 3D printing are expected to expand further across different industries.

Sustainability in Fabrication Engineering

Sustainability is a driving force behind many innovations in fabrication engineering. Victoria's engineers are focusing on developing eco-friendly fabrication processes that minimize environmental impact. This includes optimizing resource usage, reducing emissions, and recycling materials wherever possible.

By prioritizing sustainability, companies are not only meeting regulatory requirements but also appealing to environmentally conscious consumers. This shift towards green engineering practices is expected to grow as global awareness of environmental issues increases.

Conclusion

The fabrication engineering landscape in Victoria is rapidly evolving, with trends like advanced materials, automation, 3D printing, and sustainability taking center stage. As these trends continue to develop, they promise to enhance the capability and efficiency of fabrication processes across various industries.

For businesses and engineers in Victoria, staying abreast of these trends is essential for maintaining a competitive edge in the ever-changing market. By embracing these advancements, they can drive innovation and contribute to the region's economic growth.